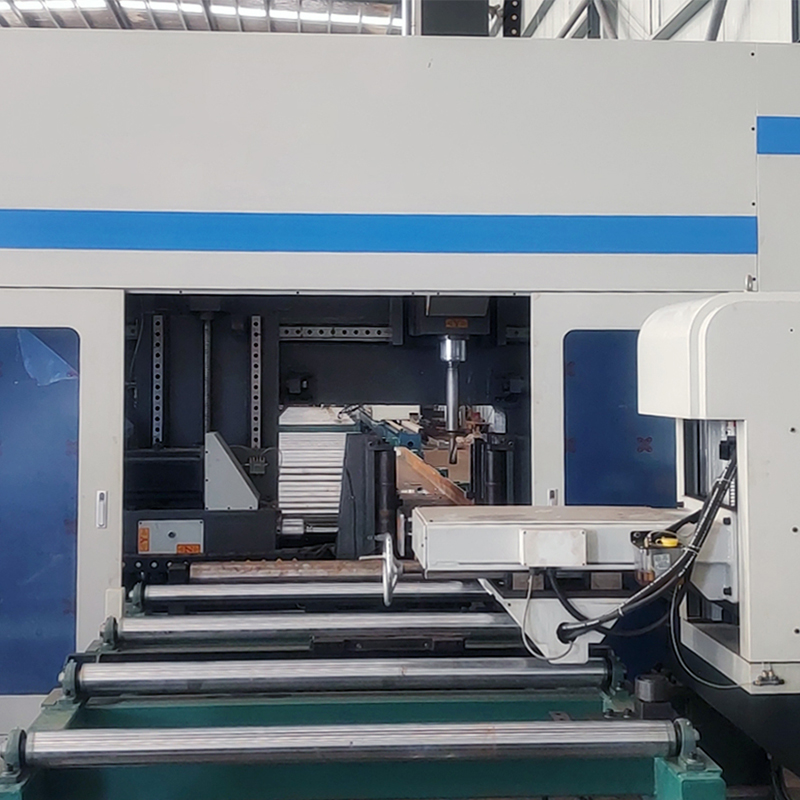

CNC H Beam Drilling Machine Model YSWZ700

CNC beam drilling machine mainly used to make holes on H beam, box beam T beam for steel structure industry, PEB industry. Used for the drilling processing of H-shape steel, box beam and channel steel of steel structure, bridge, three dimensional garage and petrol platform.Equipped with three drilling head, the drilling procedure finished after the work piece going through the equipment. Three drilling head can drill holes simultaneously, and adopt self-controlled stroke drilling head.

1. Introduction:

The production line is mainly used in drilling and sawing of H beam, U beam which are applied in the fields, such as construction, bridge, boiler, stereo garage, offshore drilling platform and, specially, in steel structure which requires high precision and easy operation. This is machine is necessary for steel structure fabrication.

2. Structure and configuration:

The combination production line consists of YSWZ700 drilling line two pairs of infeed in and outfeed conveyors ,and one CNC control device and two side conveyors, along with electrical system, hydraulic system, air cooling and lubrication.

The combination line adopts Z form arrangement that the drilling line and the band saw are installed in parallel and connected by transverse conveyor. Each of the two infeed conveyors equips a NC feeder dolly with servo motor on the datum side and side push device to push the workpiece to the datum side; the drilling line equips an automatic transverse conveyor to upload workpiece; the outfeed conveyor equips roller to move the workpiece out of the process zone and to the transverse conveyor.

In the working process, the personal should lift the workpiece to the automatic transverse conveyor, after the workpiece is uploaded to the infeed conveyor from the transverse conveyor, the side push moves the workpiece to to the datum side, and the dolly moves the workpiece to the processing zone to drill, after the drilling, the roller moves the workpiece to the outfeed conveyor, the transverse conveyor which connects drilling line and band saw moves the workpiece from the outfeed of the drilling line to the infeed of the band saw to cut the workpiece, after the cutting the workpiece is downloaded to the outfeed, and the transverse conveyor of the band saw moves the workpiece out of the processing zone.

The process sequence is from drilling to cutting, the long workpiece which is meant to process into several pieces can be drilled integrally and then cut in to pieces. The transverse conveyor between two lines in Z form arrangement can can adjust the process speed. The Z form arrange let these two lines work both together and separately, when one of them is in maintaining the another line can work independently.

3. Configuration

The combination line line includes dolly, dolly track, feed conveyor, feeding line, YSWZ700 drilling line, electrical control system, hydraulic system, air cooling system, lubrication and etc.

Terms to explain:

1. Dolly: driven by servo motor with gear box via rack and pinion, the workpiece is clamped by the jaw in order to lengthwise infeed and positioning.

2. Dolly track: bear dolly to infeed, this track can by customized.

3. Feed conveyor: consist of infeed conveyor and outfeed conveyor to bear and output the workpiece.

4. Feeding line: this transverse line consists of four in feed frames to automatically upload workpiece.

5. YSWZ700 drilling line: 3D drilling machine has three drilling heads with spindle. The side drilling head has vertical positioning, and vertical drilling head has radial positioning.

7. Hydraulic system: equip with oil tank, low pressure pump set, cooler, main valve block and other control valve unit.

8. Electrical control system: with PLC and computer, two sets of it.

9. Hydraulic system: control hydraulic movements and support hydraulic power.

10. Air cooling system: adopt mist cooling for drilling line, band saw adopts water cooling.

11. Lubrication: VERSA lubricating system, support linear guide, guide screw, bearing and etc., some other parts of this line apply artificial lubricating.

Please see the attachment of arrangement.

Specifications:

| Model | YSWZ700 |

| H-beams Max. (web height X flange width) (mm) | 700x400 |

| Min. length of workpiece (mm) | 1800 |

| Max. weight of workpiece (kg) | 5000 |

| Drilling dia. (mm) | Φ12.5~Φ30 |

| Drilling head feeding speed(mm/min) | 20~300 |

| No. of spindle | One spindle on each of three sides (top,left,right) Total: 3 spindles |

| Rotation speed (stepless speed adjustment)(rpm) | 180~560 |

| Feeding movement speed (mm/min) | 20~300 |

| Max. feeding stroke (mm) | 300 |

| Power of each spindle (kW) | 4 |

| No. of CNC axis | 4 |

| Stroke of left/right spindles (Above vertical base-level) (mm) | 20~420 |

| Stroke of top spindle (Beyond horizontal base-level) (mm) | 30~630 |

| Morse taper | 2#, 3# |

| Total power (kW) | 27 |

| Feeding type | NC carriage feeding, 20-300mm/min |

| Overall dimensions (LXWXH) (mm) | 3600x1500x2500 |

| Total weight (kg) | ≈7000 |

| Working environment | |

| Working temperature: | 0℃ ~ 40℃ |

| Power: | Three phase four wire system |

| AC Voltage: | 380V |

| Fluctuation of voltage: | ±10% |

| Frequency: | 60 Hz |

| Consist of the machine: |

| Main machine Control cabinet (MITSUBISHI) CNC carriage for feeding Optical zero reference Import software for importing CAD to CNC (dxf, dstv files only) Manual Input and Manual Programming available Dual coolant system - spray mist Morse Taper reducer sleeves Hydraulic station Chips removal Legs & Accessories for foundation leveling Documents: Manual, Maintenance Instructions, and Main Parts Drawings |

English

English Русский

Русский Español

Español العربية

العربية