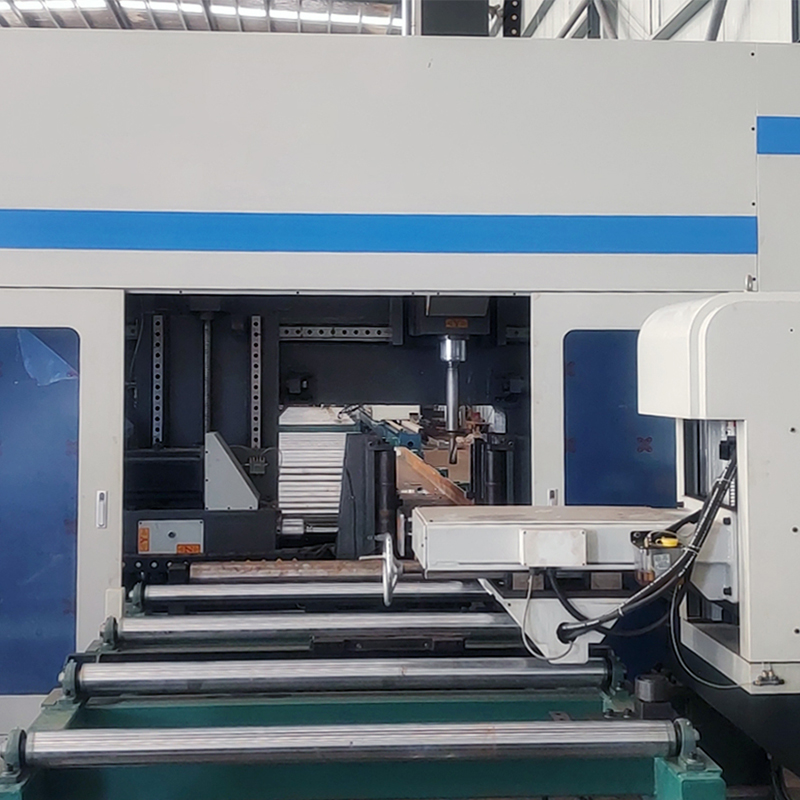

CNC H Beam Drilling Machine Model YSWZ1250

CNC beam drilling machine is mainly used for processing holes on H-beam, Channel beam with Angle beam and plate drilling and marking processing, high speed, the positioning, feeding of three spindles are all driven by servo motor. It adopts spindle servo motor, controls by YOKOGAWA PLC., and in-feeding by CNC carriage, high efficiency, and high precision; and it is wildly used in construction, bridge and tower mast & rack, with other industries.

1. Machine feature:

1), The whole machine is optimized integrated design, with high quality machine body and drilling units, which ensure high stability and high rigidity when high speed drilling. This machine is mainly composed of main machine, CNC sliding table (3), drilling spindle box (3), clamping device, detection device, cooling system, scrap box, hydraulic station, lubrication system, Tool Magazine(optional), marking unit (optional).

CNC Drilling Mchine for Beams Model YSWZ1250

Technical Specification of YSWZ1250

| Name | Unit | Value | Remark | |||

| H-beam Size | H-beam | mm | 150X75 ~ 1250X600 | |||

| Thickness | mm | ≤ 80 | ||||

| Length | m | 15 | Can be changed according to customer's requirement | |||

| Limitation to the min. H-beam | mm | Automatic Processing ≥ 3000 | ||||

| Manual Processing: 690 ~ 3000 | ||||||

| Spindle | Quantity | Pc. | 3 | |||

| Drilling Range | Left and right drilling unit | mm | ¢12.5~¢26.5 | |||

| Vertical drilling unit | mm | ¢12.5~¢33.5 | ||||

| Spindle Rotation Speed | r/min | 180 ~ 560 | ||||

| Quick change chuck | / | Morse Taper 3#,,4# | Changeable 2# | |||

| Feeding stroke | Left and right drilling unit | mm | 140 | |||

| Vertical drilling unit | mm | 240 | ||||

| Feeding Speed | mm/min | 20 ~ 300 | ||||

| Moving distance | All spindles along the length of the workpiece | mm | 520 | |||

| Left and right spindle along the up an down direction | mm | 35 ~ 570 | from the under side of the workpiece | |||

| Vertical spindle on the width of the workpiece | mm | 45 ~ 1160 | from the benchmark side | |||

| Cooling way | compressed air + atomized drilling fluid | / | / | |||

| Air Pressure | MPa | ≥ 0.5 | ||||

| Processing precision | allowance of neighbor holes distance in one hole group | mm | ≤ ±0.5 | |||

| In length of 10m, allowance of any holes distance | mm | ≤ ±1 | ||||

| Motor Power | Three phase asynchronous motor for the running of spindle | kW | 4X3 | |||

| X axis servo motor for the vertical unit | kW | 0.85 | ||||

| Z axis servo motor for the vertical unit | kW | 1.3 | ||||

| X axis servo motor of left and right side | kW | 0.85X2 | ||||

| Y axis servo motor of left and right side | kW | 1.3X2 | ||||

| Three phase asynchronous motor for moving saddle | kW | 0.55 | ||||

| Overall dimension | Length x width x height | mm | Approx.4800x2400x3300 | |||

| Total weight | kg | Approx.7000 | ||||

Technical Specification of carriage:

1) CNC axis: X axis

2) Servo motor of X axis: 5.0 Kw

3) Moving speed of X axis: 0-20m/min

4) Max. weight of feeding workpiece: 10 tons

Note:

Working temperature: ℃ ~ 40℃

Power: Three phase four wire system

AC Voltage: 380V

Fluctuation of voltage: ±10%

Frequency: 50 HZ

Relative humidity of environment: ≤ 75%

2. Main outsourcing components list of YSWZ1250

| No. | Name | Brand | Country |

| 1 | Ballscrew | NEFF/IF | Germany |

| 2 | Liner guide | HIWIN/PMI | Taiwan China |

| 3 | Towline | Kabelschlepp / Igus | Germany |

| 4 | Spray cooling pump | BIJUR | American |

| 5 | two-position &two-port valve | AIRTAC | Taiwan China |

| 6 | Automatic lubrication pump | BIJUR /HERG | American /Japan |

| 7 | PLC | Siemens | Germany |

| 8 | Servo motor | Yaskawa, Panasonic | Japan |

| Servo-Amplifier | |||

| 9 | Rotary encoder | Koyo | Japan |

| 10 | Oil pump | JUSTMARK | Taiwan China |

| 11 | Proximity Switch | Autonics | Korea |

| 12 | Photoswitch | SICK | Germany |

| 13 | Button Indicator Light | Schneider | France |

Note: The above configuration is our fixed supplier. If our supplier can not supply the components because of any special matter, we will adopt the components with the same level. But the quality is no less than the above components.

3. Accessories and spare parts list of YSWZ1250

| No. | Name | Code name | Quantity | Remark |

| 1 | Extension rod (Morse 3#) | KHQ50.1 - 6No3 | 3 pieces | Total length 150mm |

| 2 | Extension rod (Morse 4#) | KHQ50.1 - 6No4 | 1 piece | Total length 150mm |

| 3 | Drill extension rod (Morse 3#) | HZ24-9 | 1 piece | Total length 260mm |

| 4 | Drill extension rod (Morse 3#) | HZ24-10 | 1 piece | Total length 380mm |

| 5 | Adjusting wedge (Morse 1#) | SWZ10.1 - 88 | 1 | |

| 6 | Adjusting wedge (Morse 3#) | PD16.0-25 | 1 | |

| 7 | Adjusting wedge (Morse 4#) | PD16.0-26 | 1 | |

| 8 | Stepped seal ring 32 | Sd0320 | 4 | |

| 9 | J type dust ring | φ95 | 2 | |

| 10 | Nylon rope Ф20mm | 1 | Length 12m | |

| 11 | Greaser | 1 | ||

| 12 | Pressure oil can | 1 | ||

| 13 | One-way diving pump | QDX1.5-16-0.37 | 1 | Zhejiang DaYuan Pumps Industrial |

| 14 | Water Pipe Ф25mm | GB/T 1187 | 1 | Length 3m |

| 15 | Hose clamp 40 | ZBJ51002-87 | 1 | |

| 16 | Pipe joint 8 | JB/GQ0341-89 | 1 | |

| 17 | Hose clamp 20 | ZBJ51002-87 | 1 | |

| 18 | PU pipe Ф8 | 1 | Length 5m | |

| 19 | Union tee | PUT08 | 1 | |

| 20 | Morse Reducing sleeve | 3#/2# | 3 | |

| 21 | Seal ring ( 60X80X10) | GB/T 9877.1 | 2 | |

| 22 | Paint (with hardener) | 3 | 1 keg of shield color, 2 kegs of machine body color | |

| 23 | Filter element | HX-63X20Q | 1 | Hydraulic element |

| 24 | CD | 1 |

English

English Русский

Русский Español

Español العربية

العربية