CNC Drilling Machine for H Beam Model YSWZ1000

CNC Beam Drilling machine production line is mainly used in drilling and sawing of H beam, U beam which are applied in the fields, such as construction, bridge, boiler, stereo garage, offshore drilling platform and, specially, in steel structure which requires high precision and easy operation. This is machine is necessary for steel structure fabrication.

Configuration

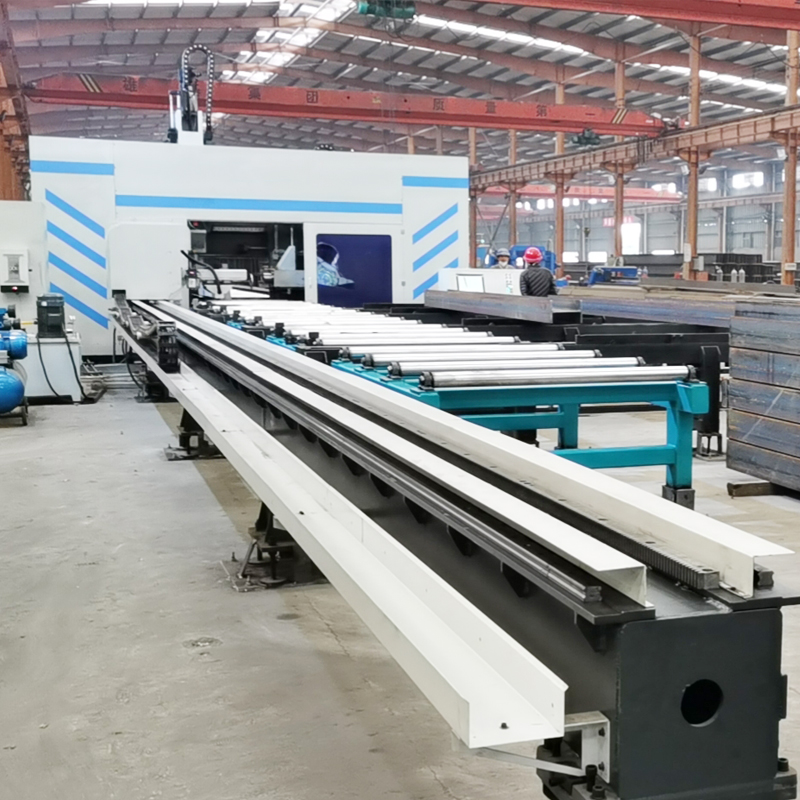

The combination line line includes dolly, dolly track, feed conveyor, feeding line, YSWZ1000 drilling line, electrical control system, hydraulic system, air cooling system, lubrication and etc.

Terms to explain:

1. Dolly: driven by servo motor with gear box via rack and pinion, the workpiece is clamped by the jaw in order to lengthwise infeed and positioning.

2. Dolly track: bear dolly to infeed, this track can by customized.

3. Feed conveyor: consist of infeed conveyor and outfeed conveyor to bear and output the workpiece.

4. Feeding line: this transverse line consists of four in feed frames to automatically upload workpiece.

5. YSWZ1000 drilling line: 3D drilling machine has three drilling heads with spindle. The side drilling head has vertical positioning, and vertical drilling head has radial positioning.

7. Hydraulic system: equip with oil tank, low pressure pump set, cooler, main valve block and other control valve unit.

8. Electrical control system: with PLC and computer, two sets of it.

9. Hydraulic system: control hydraulic movements and support hydraulic power.

10. Air cooling system: adopt mist cooling for drilling line, band saw adopts water cooling.

11. Lubrication: VERSA lubricating system, support linear guide, guide screw, bearing and etc., some other parts of this line apply artificial lubricating.

Please see the attachment of arrangement.

CNC Drilling Machine for Beams Model YSWZ1000

1. Technical Specification of YSWZ1000

| Name | Unit | Value | Remark | ||

| H-beam Size | H-beam | mm | 150X75~1000x500 | ||

| Thickness | mm | ≤80 | |||

| Length | m | 12m | Can be changed according to customer's requirement | ||

| Limitation to the min. H-beam | mm | Automatic Processing ≥3000 | |||

| Manual Processing:690 ~ 3000 | |||||

| Spindle | Quantity | Pc. | 3 | ||

| Drilling Range | Left and right drilling unit | mm | ¢12~¢26.5 | ||

| Vertical drilling unit | mm | ¢12~¢33.5 | |||

| Spindle Rotation Speed | r/min | 180~560 | |||

| Quick change chuck | / | Morse Taper 3#、4# | Changeable 2# | ||

| Feeding stroke | Left and right drilling unit | mm | 140 | ||

| Vertical drilling unit | mm | 325 | |||

| Feeding Speed | mm/min | 20~300 | |||

| Moving distance | All spindles along the length of the workpiece | mm | 520 | ||

| Left and right spindle along the up an down direction | mm | 35 ~ 470 | from the under side of the workpiece | ||

| Vertical spindle on the width of the workpiece | mm | 45 ~ 910 | from the benchmark side | ||

| Cooling way | compressed air + atomized drilling fluid | / | / | ||

| Air Pressure | MPa | ≥0.5 | |||

| Processing precision | allowance of neighbor holes distance in one hole group | mm | ≤0.5 | ||

| In length of 10m, allowance of any holes distance | mm | ≤1 | |||

| Motor Power | Three phase asynchronous motor for the running of spindle | kW | 4x3 | Quantity of spindle: 3 | |

| X axis servo motor for the vertical unit | kW | 1.0 | |||

| Z axis servo motor for the vertical unit | kW | 1.5 | |||

| X axis servo motor of left and right side | kW | 1.0X2 | |||

| Y axis servo motor of left and right side | kW | 1.5X2 | |||

| Three phase asynchronous motor for moving saddle | kW | 0.55 | |||

| Overall dimension | LengthXwidthXheight | mm | About 4400x2400x3500 | ||

| Total weight | kg | About 6000 | |||

Technical Specification of carriage:

1) CNC axis: X axis

2) Servo motor of X axis: 5.0 Kw

3) Moving speed of X axis: 0-15m/min

4) Max. weight of feeding workpiece: 10 tons

Note: Working temperature: 0℃ ~ 40℃

Power: Three phase four wire system

AC Voltage: 380V

Fluctuation of voltage: ±10%

Frequency: 50 HZ

2. Accessories and spare parts list of YSWZ1000

| No. | Name | Code Name | Quantity | Remark |

| 1 | Extension rod (Morse 3#) | KHQ50.1 - 6No3 | 3 pieces | Total length150mm Installed in the machine |

| 2 | Extension rod (Morse 4#) | KHQ50.1 - 6No4 | 1 piece | Total length 150mm Installed in the machine |

| 3 | Drill extension rod (Morse 3#) | HZ40.325-48A | 1 piece | Total length 330mm Installed in the machine |

| 4 | Drill extension rod (Morse 3#) | HZ40.325-48D | 1 piece | Total length 480mm Installed in the machine |

| 5 | Pressure head | SWZ10.3-24A | 4 | Include these installed in the machine |

| 6 | Adjusting wedge (Morse 1#) | SWZ10.1 - 88 | 1 | Installed in the machine |

| 7 | Adjusting wedge (Morse 3#) | PD16.0-25 | 1 | |

| 8 | Adjusting wedge (Morse 4#) | PD16.0-26 | 1 | |

| 9 | J type dust ring | ¢95 | 2 | |

| 10 | Nylon rope Ф20mm | 1 | 12m | |

| 11 | Greaser | 1 | ||

| 12 | Pressure oil can | 1 | ||

| 13 | One-way diving pump | QDX1.5-16-0.37 | 1 | Zhejiang DaYuan Pumps Industrial |

| 14 | Water Pipe Ф25mm | GB/T 1187 | 1 | Length 3m |

| 15 | Hose clamp 40 | ZBJ51002-87 | 1 | |

| 16 | Pipe joint 8 | JB/GQ0341-89 | 1 | |

| 17 | Hose clamp 20 | ZBJ51002-87 | 1 | |

| 18 | PU pipe Ф8 | 1 | Length 5m | |

| 19 | Seal ring ( 60X80X10) | GB/T 9877.1 | 2 | |

| 20 | Union tee | PUT08 | 1 | |

| 21 | Stepped seal ring 32 | Sd0320 | 4 | |

| 22 | Morse Reducing sleeve | 3#/2# | 3 | |

| 23 | Paint (with hardener) | 1 keg of shield color, 2 kegs of machine body color | ||

| 24 | Filter element | HDX-63X20Q | 1 | Hydraulic element |

| 25 | CD | 1 |

3. Main outsourcing components list of YSWZ1000

| Serial No. | Name | Brand | Country |

| 1 | Hydraulic Valve | ATOS/Justmark | Italy/ Taiwan China |

| 2 | Servo Motor | Panasonic | Japan |

| 3 | Servo Amplifier | Panasonic | Japan |

| 4 | Ballscrew | NEFF/IF | Germany |

| 5 | PLC | Siemens | Germany |

| 6 | Rotary Encoder | Koyo | Japan |

| 7 | Atomized Cooling Pump | Bijur | America |

| 8 | Flexible Extended Nozzle | Bijur | America |

| 9 | Pneumatic Dual Member | SMC | Japan |

| 10 | Solenoid Valve | AIRTAC | Taiwan China |

| 11 | Proximity Switch | Autonics | Korea |

| 12 | Photoswitch | SICK | Germany |

| 13 | Button Indicator Light | Schneider | France |

Note: The above is our fixed supplier. If the supplier can not supply the components in case of any special matter, we will adopt the components with the same level, but the quality is no worse than the above.

2. Structure and configuration:

The combination production line consists of YSWZ1000 drilling line two pairs of infeed in and outfeed conveyors ,and one CNC control device and two side conveyors, along with electrical system, hydraulic system, air cooling and lubrication.

The combination line adopts Z form arrangement that the drilling line and the band saw are installed in parallel and connected by transverse conveyor. Each of the two infeed conveyors equips a NC feeder dolly with servo motor on the datum side and side push device to push the workpiece to the datum side; the drilling line equips an automatic transverse conveyor to upload workpiece; the outfeed conveyor equips roller to move the workpiece out of the process zone and to the transverse conveyor.

In the working process, the personal should lift the workpiece to the automatic transverse conveyor, after the workpiece is uploaded to the infeed conveyor from the transverse conveyor, the side push moves the workpiece to to the datum side, and the dolly moves the workpiece to the processing zone to drill, after the drilling, the roller moves the workpiece to the outfeed conveyor, the transverse conveyor which connects drilling line and band saw moves the workpiece from the outfeed of the drilling line to the infeed of the band saw to cut the workpiece, after the cutting the workpiece is downloaded to the outfeed, and the transverse conveyor of the band saw moves the workpiece out of the processing zone.

The process sequence is from drilling to cutting, the long workpiece which is meant to process into several pieces can be drilled integrally and then cut in to pieces. The transverse conveyor between two lines in Z form arrangement can can adjust the process speed. The Z form arrange let these two lines work both together and separately, when one of them is in maintaining the another line can work independently.

English

English Русский

Русский Español

Español العربية

العربية