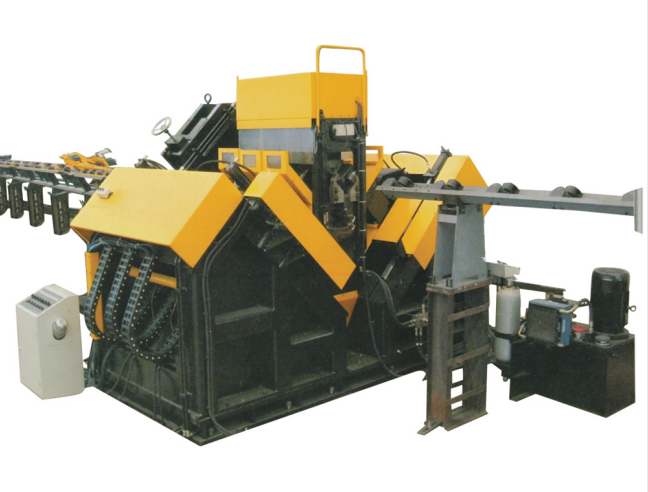

CNC High Speed Marking and Drilling Machine for Angles Model JGZ3635H

JGZ-3635H CNC Angle Steel High Speed Drilling, Marking Production Line is a special equipment for high speed Angle steel drilling and stamping which is newly developed and developed by our company. The machine is controlled by numerical control system. The structure of the whole machine is compact, which greatly improves the production efficiency.

JGZ3635 high speed marking and drilling machine for angles

1.Brief Introduction

JGZ-H CNC Angle Steel High Speed Drilling, Marking Production Line is a special equipment for high speed Angle steel drilling and stamping which is newly developed and developed by our company. The machine is controlled by numerical control system. The structure of the whole machine is compact, which greatly improves the production efficiency.

2.Basic configuration of the machine

2.1 Mechanical part

| Serial No. | Item | JGZ3635H |

| 1 | Total length | 30000mm |

| 2 | Quantity of feeding table | 4group |

| 3 | Quantity of overturning tables | 4group |

| 4 | Quantity of feeding driver | 1 set |

| 5 | Length of feeding passage | 16700mm |

| 6 | Length of the host | 2650mm |

| 7 | Length of finished passage | 10000mm |

| 8 | Pneumatic control system | 1 set |

| 9 | Hydraulic control system | 1 set |

| 10 | Feeding direction | According to user requirements |

| 11 | The purchaser is responsible for the part | Embedded plates and anchor bolts required for the cement foundation and equipment of the installation site shall be prepared according to the foundation drawing provided by the supplier |

2.2 Main Components List:

| No. | Name | Model | Manufacturer | |

| Main Electric Components | ||||

| 1 | PLC | Japan YASAKAWA | ||

| 2 | Servo Motor & servo driver of A/B axis | 2 kW | Japan Panasonic | |

| 3 | Servo Motor & servo driver of spindle | 2 kW | ||

| 4 | Servo Motor & servo driver of X axis | 5 kW | ||

| 5 | Main motor | 11kW | Shanghai SNMA | |

| 6 | Transducer | 11kW | SIMENS | |

| 7 | Business Computer | LCD screen | China Lenovo | |

| 8 | Photoelectric Switch | Measure length | Korea AUTONICS | |

| 9 | Travel switch | TZ-8104 | Taiwan TEND | |

| 10 | Rotary Encoder | Detection | Japan OMRON | |

| 11 | Proximity Switch | Normal open | Korea AUTONICS | |

| 12 | Normal close | |||

| Main Hydraulic Pressure Components | ||||

| 1 | Electromagnetic Change Valve | Italy ATOS | ||

| 2 | Stack Check Valve | Italy ATOS | ||

| 3 | Italy ATOS | |||

| 4 | Reducing Valve | Italy ATOS | ||

| 5 | Stack Reducing Valve | Italy ATOS | ||

| 6 | Electromagnetic Overflow Valve | Italy ATOS | ||

| 7 | Speed Controlling Valve | Italy ATOS | ||

| 8 | Direction Control Valve | Italy ATOS | ||

| 9 | Italy ATOS | |||

| 10 | Stack Overflow Valve | Italy ATOS | ||

| Main Pneumatic Components | ||||

| 1 | Carriage | Up Cylinder | Taiwan AirTAC | |

| 2 | Clamp Cylinder | Taiwan AirTAC | ||

| 3 | Electromagnetic Gas-valve | Taiwan AirTAC | ||

| 4 | Unload Conveyor | Overturn Cylinder | Taiwan AirTAC | |

| 5 | Electromagnetic Gas-valve | Taiwan AirTAC | ||

| Main Mechanical Components | ||||

| 1 | Drilling unit | Precision machinery | BT40 | Taiwan KENTURN |

| 2 | Linear guide | Taiwan hIWIN | ||

| 3 | Ball screw | Taiwan HIWIN | ||

3.Technical parameters of the machine

| No. | Item | JGZ3635H |

| 1 | Angle size Range | 130*130*10-360*360*35mm |

| 2 | Max. Length of workpiece | 12000mm |

| 3 | Length of finished passage | 10000mm |

| 4 | The adjusting range of stadia | 40-340mm |

| 5 | Drilling diameter | Φ17-Φ40mm |

| 6 | Max. Speed of drilling spindle | 6000 r/min |

| 7 | The number of drilling spindle | Each side 3, a total of 6 |

| 8 | The hole of spindle | BT40 |

| 9 | The way of tool clamping | Pneumatic play knife, Broach rod |

| 10 | The number of CNC Axis | 9 |

| 11 | Variable frequency motor power of drilling spindle | 6*15KW |

| 12 | Servo motor of feeding driver | 5KW |

| 13 | Marking force(kN) | 1200 |

| 14 | Qty of typing groups | 1Group |

| 15 | Number of character | 18 |

| 16 | Character size(mm) | 14X10X19 |

| 17 | Max. feeding speed(m/min) | 90 |

| 18 | Cooling way | High pressure spray cooling |

| 19 | The total power of machine(kW) | About 120KW |

| 20 | Programming Mode | Input by keyboard, RS232, CAD floppy disk input &USB interface |

| 21 | Lubrication method | Equipped with automatic lubrication |

| 22 | Fabrication Precision | Hole diameter tolerance: 0-0.8mm |

| Dmax-Dmin: Dmax-Dmin: ≤1.2mm | ||

| Angle steel reference deviation: ≤0.7mm | ||

| Hole perpendicularity error: ≤0.03tmm(T is the thickness of the workpiece), And no greater than 2mm |

4.Working Environment

| 1 | Power Supply | Three-phase four-wire system |

| 2 | Voltage | 415V±10% |

| 3 | Frequency | 50Hz |

| 4 | Operating temperature | 0℃-40℃ |

| 5 | Relative Humidity | <90% No condensation |

| 6 | Air Compressed | Pressure: 0.8MPa |

5. Machine Configuration Introduction

The machine is mainly composed of feeding table, turning feeding table, feeding channel, feeding trolley, drilling unit, typing unit, finished material channel, electrical system, hydraulic system, cooling system, etc.

Tool List with the Machine

Provide the foundation drawings of machine

Tool List with the Machine

| Serial NO | Item | QTY. | Mark |

| 1 | Type mould | 1pc | |

| 2 | Character(number,letter) | 1pc each | Including the one installed on the machine |

| 3 | Upper clamp claw, nether clamp claw | 1 pc | Including the one installed on the machine |

| 4 | Shank | 7pc | Including the one installed on the machine |

| 5 | Knife back | 7pc | Including the one installed on the machine |

| 6 | Blade | 12pc | Including the one installed on the machine |

| 7 | Approach switch | 2pc | |

| 8 | Hex Wrenches | 1set | 4~17mm |

| 9 | Straight screwdriver | 1pc | |

| 10 | Cross head driver | 1pc | |

| 11 | 450 adjustable spanner | 1pc | |

| 12 | Fork wrench | 1set | |

| 13 | Feeler gauge | 1pc | |

| 14 | Machinery instruction | 1set | |

| 15 | Electrical manual instruction | 1set | |

| 16 | Packing list | 2pc | Attached to the instruction |

| 17 | Certificate of conformity | 2pc | Attached to the instruction |

Free sample testing:

For free sample making/testing, please send your samples or products CAD drawings, we can test run the machine and show you machine test running.

Progressing Solution Design

According to customer's product processing requirement, we can design the unique solution that supports higher manufacturing efficiency and better processing quality for customer.

After-sales service:

Training for installation and service:

1) We will supply the machine with training video and user's manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by e-mail, whatsapp, Wechat, telephone/MSN/ICQ and so on, when you meet some problems of installation, using or adjusting.

2) You can come to our factory for inspection and training. We will provide professional guide. Direct and effective face-to-face training. Here we have assembled equipment, all sorts of tools and testing facility,we will also provide accommodation during training period.

3) The Strong after--sale service team in China, Our engineers (staffs) can speak fluent English to communicate and solve question when you have requirement calendar day per person.

4) Depending on the region, If need our engineer to visit for installation, we will dispatch engineer for installation and service at your site.

Installation and Training Time: 3-5 working days(Recommend)..

Warranty:

The guarantee period of quality shall be 12 months counting from the date on which the machine finished installation and accept by Buyer. We are responsible for providing the free of charge during the guarantee period. If out of guarantee time, all damaged parts are charged.

English

English Русский

Русский Español

Español العربية

العربية