Angle Punching Machine

Product Feature:

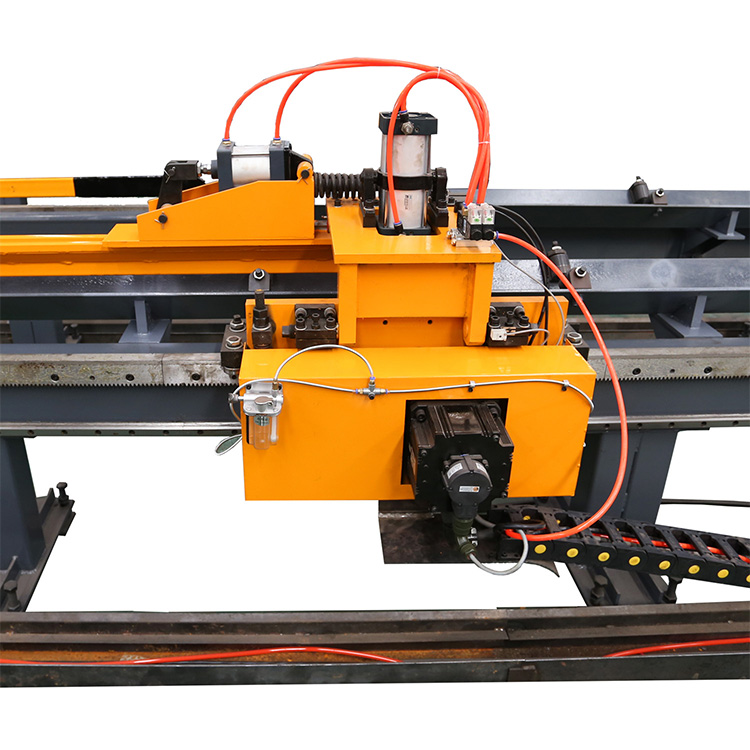

1. Adopt CNC technology, servo motor infeeding, with high efficiency, stable workpiece precision. Key hydraulic, pneumatic and electric parts all imported.

2. There are three sets of punch and die on each side which can install three kinds of punches with different diameters, can process all holes once time.

Computer with Chinese/English interface, easy operation, and can display the drawing of workpiece. Easy programming, can manual programming and also can use the program generated by lofting software. It can read .NC1 files generated by TEKLA & BOCAD software.

4. CNC infeed carriage is driven by servo motor. The photoelectric encoder feeds back the information. Closed loop control to ensure high positioning precision.

2. Basic configuration of the machine

2.1 Mechanical part

| No. | Item | YJX1010 |

| 1 | Total length | 24200mm |

| 2 | Quantity of feeding table | 3 group |

| 3 | Quantity of overturning tables | 3 group |

| 4 | Quantity of feeding driver | 1 group |

| 5 | Length of feeding passage | 15800mm |

| 6 | Length of the host | 2100mm |

| 7 | Length of finished passage | 6m |

| 8 | Pneumatic control system | 1 Group |

| 9 | Hydraulic control system | 1 Group |

| 10 | Feeding direction | According to user requirements |

| 11 | Integrated hydraulic station | Yes |

| 12 | The purchaser is responsible for the part | Embedded plates and anchor bolts required for the cement foundation and equipment of the installation site shall be prepared according to the foundation drawing provided by the supplier |

2.2 Electronic control part

| 1 | Numerical Control System | PLC Control System |

| 2 | Driving System | Panasonic Servo Motor |

3. Technical parameters of the machine

| No. | Item | Commodity |

| YJX1010 | ||

| 1 | Angle Beam Range(Mm) | 38*38*3-100*100*10 |

| 2 | Max Punching Diameter | Φ26mm(Q235, Q345), punching of special-shaped holes and oblong holes can be achieved by changing the mold |

| 3 | Max Punching force(KN) | 700KN |

| 4 | Punching Side | 2 Sides |

| 5 | Number of die per side | 2 Pcs |

| 6 | Typing ability(KN) | 700KN |

| 7 | Qty of typing groups | 4 Groups |

| 8 | Digit number of each group | 12 Pcs |

| 9 | Character size | (L*W*H)14*10*19mm |

| 10 | Shearing force(KN) | 1250KN |

| 11 | Shearing method | Single Blade Shearing |

| 12 | CNC Axis | 3 Axis |

| 13 | Length of Blank Workpiece(M) | 12 M |

| 14 | Max Length of Workpiece(M) | 12 M |

| 15 | Length of finished workpiece(M) | 10 M |

| 14 | Discharging method of finished products | The finished material channel is pushed manually and turned out to one side. The power source for turning out is pneumatic. |

| 16 | Angle Beam feeding speed | Max 90m/min |

| Punching speed(times/min) | Average 50-60 times/min | |

| 17 | Programming Mode | Input by keyboard, RS232, CAD floppy disk input &USB interface |

| 18 | Lubrication method | Equipped with automatic lubrication |

| 19 | Fabrication Precision | Hole diameter tolerance: 0-0.8mm |

| Dmax-Dmin: ≤1.2mm Aperture roundness tolerance range: Dmax-Dmin: ≤1.2mm | ||

| Hole perpendicularity error: ≤0.36mm | ||

| Distance tolerance of two adjacent holes in the same group: ±0.5mm | ||

| The hole distance tolerance of two non-adjacent holes in the same group: ±0.7mm | ||

| End distance tolerance : ±1.2mm | ||

| Shearing length tolerance: ±1mm | ||

| Verticality of cut surface: ≤1.2mm |

4. Working Environment

| 1 | Power Supply | 3 Phase 4 Wire System |

| 2 | Voltage | 415V(or 380V or 220V)±10% |

| 3 | Frequency | 50Hz or 60HZ |

| 4 | Operating temperature | 0℃-40℃ |

| 5 | Relative Humidity | <90% No condensation |

| 6 | Air Compressed | Pressure: 0.8MPa Flow rate: 1.0m³/h |

5. Machine Configuration Introduction

YJX-1610 New Type High-Speed CNC Angle Steel Punching Typing & Shearing Machine is mainly composed of feeding table, turning feeding table, feeding channel, feeding trolley, punching unit, typing unit, shearing unit, finished material channel, electrical system, hydraulic system, etc.

English

English Русский

Русский Español

Español العربية

العربية